Computational Design of Wind-up Toys

- Peng Song1

- Xiaofei Wang1

- Xiao Tang1

- Chi-Wing Fu2

- Hongfei Xu1

- Ligang Liu1

- Niloy J. Mitra3

1University of Science and Technology of China 2The Chinese University of Hong Kong 3University College London

SIGGRAPH Asia 2017

Abstract

Wind-up toys are mechanical assemblies that perform intriguing motions driven by a simple spring motor. Due to the limited motor force and small body size, wind-up toys often employ higher pair joints of less frictional contacts and connector parts of nontrivial shapes to transfer motions. These unique characteristics make them hard to design and fabricate as compared to other automata. In this paper, we present a computational system to aid the design of wind-up toys, focusing on constructing a compact internal wind-up mechanism to realize user-requested part motions. Our key contributions include an analytical modeling of a wide variety of elemental mechanisms found in common wind-up toys, including their geometry and kinematics, conceptual design of wind-up mechanisms by computing motion transfer trees that support the requested part motions, automatic construction of wind-up mechanisms by connecting multiple elemental mechanisms, and an optimization on the geometry of parts and joints with an objective of compacting the mechanism, reducing its weight, and avoiding collision. We use our system to design wind-up toys of various forms, fabricate a number of them using 3D printing, and show the functionality of various results.

System Overview

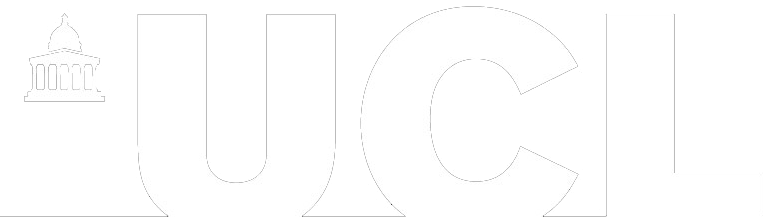

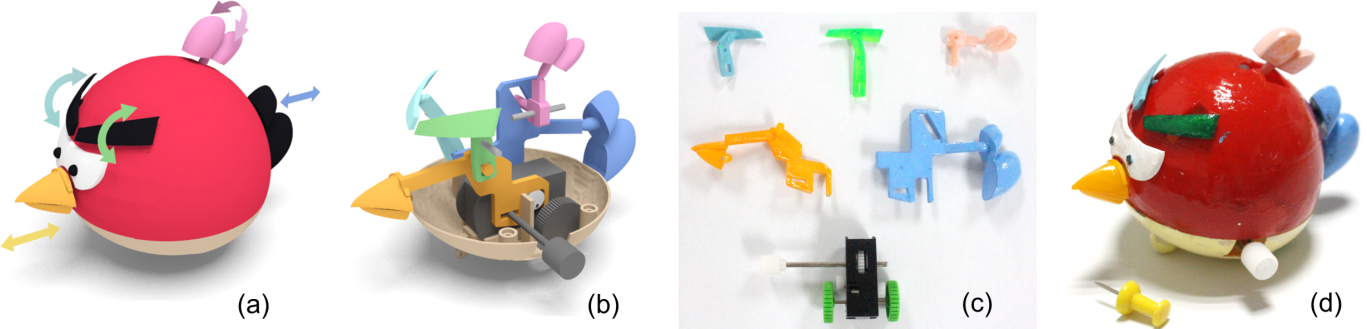

Overview of our system. (a) Segmented Teapot model (i.e., body, handle, spout, and lid) with user-provided motion on each end-effector part (motion arrows and axes colored in red); (b) our system first constructs motion transfer trees to guide the selection of elemental mechanisms; (c) then, it orientates and connects elemental mechanisms to form an initial wind-up mechanism, (d) optimizes the joints and parts in each elemental mechanism with a kinematic analysis, subject to fabrication and collision constraints, and (e) post-processes the toy to refine parts boundary shape, and create the body shell and support structures for fabrication. (f) The 3D-printed wind-up toy result.

Results

Some of the wind-up toys produced from our system; from left to right: Bunny, Horse, Mickey, Dragon, Tree, and House. From top to bottom: input models and prescribed toy part motions, the optimized wind-up mechanisms, and the associated motion transfer trees, where we color the nodes connected to the external toy parts in orange.

Four of the six wind-up toys (top) that we have fabricated and assembled from 3D-printed parts (bottom). From left to right: Bunny (13.0g shell + 7.8g motor + 9.0g mechanism), Horse (15.3g shell + 5.9g motor + 26.1g mechanism), Flower Pot (34.8g shell + 5.8g motor + 8.0g mechanism), and House (48.9g shell + 6.0g motor + 6.4g mechanism).

Bibtex

@article{Song:SIGA:2017,

author = {Song, Peng and Wang, Xiaofei and Tang, Xiao and Fu, Chi-Wing and Xu, Hongfei and Liu Ligang and Mitra, Niloy J.},

title = {Computational Design of Wind-up Toys},

journal = {{ACM} Transactions on Graphics},

volume = {36},

number = {6},

month = November,

year = {2017},

articleno = {238},

numpages = {13},

ISSN = {0730-0301},

doi = {10.1145/3130800.3130808}

}

Acknowledgements

We thank the reviewers for the valuable comments, and Thingiverse for providing 3D models of Angry Bird, Horse, Dragon, Tree, Flower Pot, Minion, and Gecko. This work is supported in part by the National Natural Science Foundation of China (61403357, 61672482, 11626253), the One Hundred Talent Project of the Chinese Academy of Sciences, the Hong Kong RGC General Research Funding Project (14203416), the ERC Starting Grant SmartGeometry (StG-2013-335373), and gifts from Adobe.